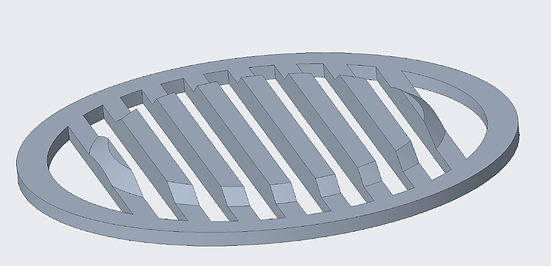

CAD for Original Design

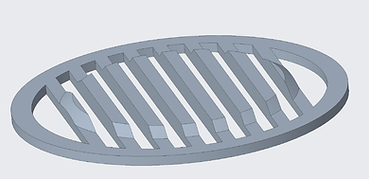

This is the CREO design for part #19 in the assembly. This is called the honey-comb air intake grate. It is made from low-carbon steel and deforms plastically under low pressures.

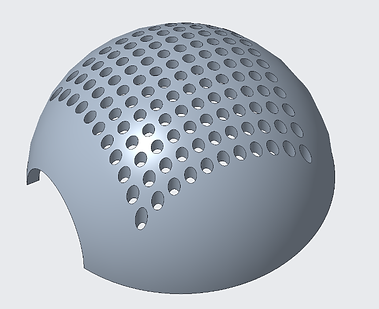

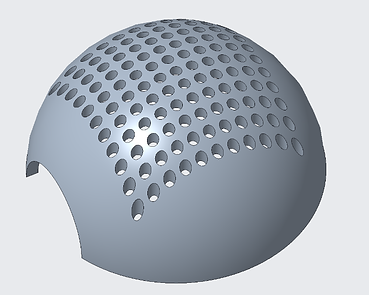

Above is a model of the back shell of the hair dryer (part #18). Outer casing back is made of polypropylene and is rigid and does not deform or become mushy under operating temperatures.

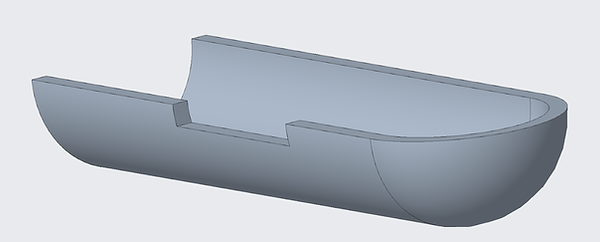

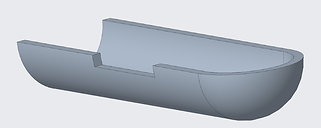

Above is simplified CREO model of the outer casing front (part #17). Like the rest of the hair dryer frame, this part is made from a blend of polypropylene. Considering that the heating coil lodges inside this section of the cone, the outer casing front will heat up when the hair dryer is operating under the high heating mode.

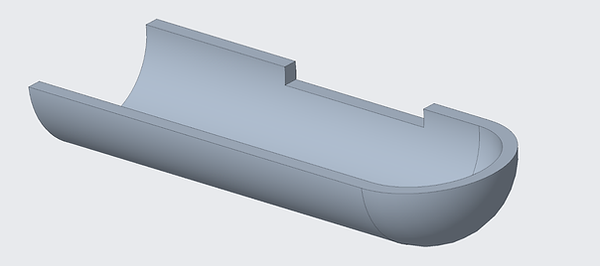

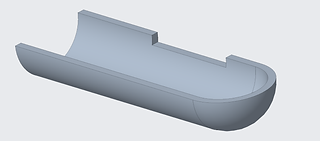

Above are two mirrored parts that serve as the hair dryer handles (handle_right, part #1; handle_left, part #2). These are also injection molded polypropylene. This section of the product does not heat up. When clasped together with screws, the handle houses the manual switch for selecting heating modes.

Above is the assembly view for these five parts. We see that the model assembly is a simplified version of the real-life product. The real product has an odd spline curve for both the outer casing front and the handle section.

There are three key components to this assembly that deserve noticing. Firstly, it is necessary for the outer casing back to have a porous or slotted surface to allow intake air to enter the heating chamber. Secondly, the honey-comb air intake grate has several possible design patterns--which affects the air patterns that could drastically change the heating speed and conduction which dries hair. Thirdly, in the handle of the current product, there is a slot for the heating selection switch.

Original Cost Analysis

Firstly, we look at the possible price comparison of the honey-comb air intake grate. From McMaster-Carr, similarly processed perforated carbon-steel sheets are found for $137.04 for a 48” X 96” sheet. The diameter of the air intake grate is 3.” Adjusting for space in between circular punches, at least 450 circular grates could be cut from the steel sheet. At this rate, price is 30 cents per grate. Because wholesale prices are considerably lower than retail, it is a safe estimation to say that each grate could be purchased wholesale from a manufacturer for around 15 cents per grate.

Next, we look at the polypropylene outer shell back. This shape is spherical and is like a plastic water bottle. There is a similarly sized polypropylene plastic bottle sold by McMaster-Carr that sells for $2.62. This bottle however is larger than the hair-dryer component, and it also has threading for the screw cap. These two factors suggest that manufacturing the half spherical hair dryer back will cost significantly less than the McMaster-Carr bottle. On the other hand, the dryer back involves perforated surfaces to allow air to enter the heating chamber. This modification to a plane polypropylene sheet will add to the cost of manufacturing. Considering all these factors, I estimate a wholesale price of 35 cents per shell back.

Next--the polypropylene shell front. This shape tapers from a large diameter circle to a smaller diameter circle. This general shape is reminiscent of a funnel. McMaster-Carr sells a similarly shaped polypropylene funnel for $1.59. The cost of injecting this funnel must be close to nothing. Taking this into consideration, I believe that the cost to buy this cone-shaped front wholesale is less than 60 cents.

Finally, the two polypropylene handles are very close to the water-bottle shape. Assuming a similar process to the outer shell back, we can assume the pair of handles together cost 70 cents to buy wholesale.

All together, all the polypropylene shell components along with the carbon-steel grate costs a total of $1.80. This is a reasonable estimation because the motor and heater coil and electrical switches and power chord all cost extra. This does not include an assembly or processing costs (like drilling or tapping holes).