The product to be repurposed is a furnace air filter. High MERV (minimum efficiency reporting value) rated air filters provide a barrier against biological and viral constituents. It is important to use air filters which have a high MERV rating of 12+ because of their capabilities to filter out small particles and airborne droplets which may contain the virus. Using filters with an MERV rating of less than 12 can be potentially dangerous as for these reasons. The user should also make sure that the air filter they wish to repurpose does not contain fiber glass, which, when breathed in can become an irritant and cause pulmonary complications. The use of the filtering material found in air filters can enhance home made mask design in a time when protective face masks are becoming scarce.

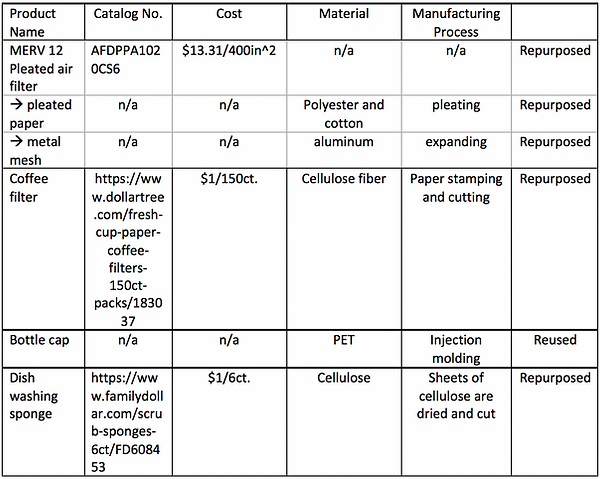

Bill of Materials:

Disassembly:

Disassembly of these products is incredibly easy and safe. The user should begin by separating the filter form the paper casing of the filter assembly. This can easily be done by using scissors. Be mindful of cutting the metal mesh since it can become sharp. Loose bottle caps and buttons can be found around the house, if not then disassembly is also very simple. Simply twist to remove a bottle cap.

Design for Assembly

Design for Assembly asks the following questions:

Does a particular part move relative to all other parts in the assembly? Only large motions need to be considered, not small movements, deflections, or hinging motions.

No. No parts on the face mask more nor are they designed to do so. The face mask should be secured to the face to prevent any movement.

Must a particular part be made of a different material than other parts in the assembly, or must it be isolated from other parts? Only fundamental reasons concerned with required material properties are acceptable for using a different material.

No parts need to be made from a different material. The only exception to this is the band that wraps the mask to the face – given the elastic properties that are different than those of cloth. However, it is not necessary that this part be elastic.

Must a particular part be separate from other parts of the assembly in order to make assembly, disassembly, or maintenance possible?

Yes. When assembling, the band that secures the mask to the wearers head must be separate from the filter mask material as it undergoes pressing to get the desired mask shape.

Typically, the goal of DFA is to eliminate parts. However, in this case all parts are necessary and there are no parts to eliminate. One potential way to eliminate the number of parts is to have the band be made of the same filter material. This would make all one part. However, without the elasticity of the band, the material bands would have to be tied around the head. Face masks are generally very simple devices and have minimal parts.

What are the Number of Parts in the assembly?

There are only two separate parts in a surgical mask assembly: The filter material, and the band.

The “Theoretical Minimum Number of Parts” in the assembly:

Given that both these parts serve separate functions and are both required. This assembly already has the minimum number of parts: 2.