New Concepts

The first idea to improve the recyclability of this product is to eliminate the handle. A cone with a more “coffee cup” shape could be fitted with rubber ridges for grip and heat-protection. This eliminates the cost to mold the handle pieces as well as cuts down on plastic material usage. If the max operating temperature of the hair dryer was reduced by 20 C, the front metal grate could be replaced with polypropylene. This would make the body of this hair dryer 1 single material. Because recyclers have issues with separating products by their components to produce high quality singular material bails, this would address the issue by increasing the percentage of single material.

Below is a sketch of the coffee-cup dryer. For the most part, the insides of the hair dryer would remain the same. The only difference would be fitting a different low-profile switch into the side of the dryer (instead of inside the handle).

The second idea to improve the recyclability of this product is to change the body material from polypropylene to another easily recycled material. The new material for this hair dryer must have a high enough operating temperature. It must be strong and preferably light weight. Steel is the most commonly recycled material in the U.S. today. The problem with using metals for this hair dryer is its high thermal conductivity. The metal frame would suck so much heat from the heating compartment and redirect it into the surrounding free air and the user’s hand. So, while metals would be recycled well, the thermal conductivity and the overall weight make these materials poor options. Another recyclable plastic such as PETE has a high enough operating temperature to work for this hair dryer, but there’s no clear advantage for using PETE over PP. One other option is to use rubber. Rubber would have the thermal properties and mechanical strengths to work as a hair dryer frame. There might even be some advantages to using rubber--such as not breaking if dropped. While there are some mechanical advantage, the mechanical disadvantage is the flexibility of the frame which might interfere with moving fan blades—causing inside damage. One serious disadvantage is the price. The cost of rubber in the U.S. is over $2 per pound while polypropylene cruises at a low $0.13 per pound.

The third idea to improve the recyclability of this hair dryer is to redesign the frame to disassemble easily without any special tools. As mentioned earlier, a huge issue with recycling is separating materials into high-percentage material bails. If this whole hairdryer was discarded and compacted into a PP bail, all the electronics and steel (impurities) would lower the grade of the recycling bail. If there were instructions and an easy way to disassemble the hair dryer into the PP frame and the other odds and ends, this would greatly help the recycling process. Screws are the current fasteners being used in this hair dryer. An alternative joining option that could be incorporated into the design is shown below.

A fastening as shown above would be able to join two polypropylene frame parts and be easily pushed-in and snapped apart to break the frame into same-material components.

Pugh Matrix

From the Pugh matrix, we conclude that option 1 (eliminating the hair dryer handle) provides several benefits that outweigh the other viable options.

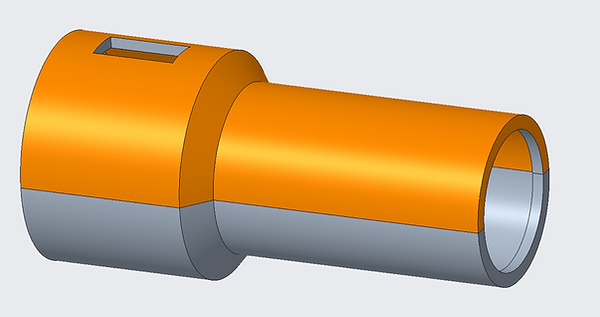

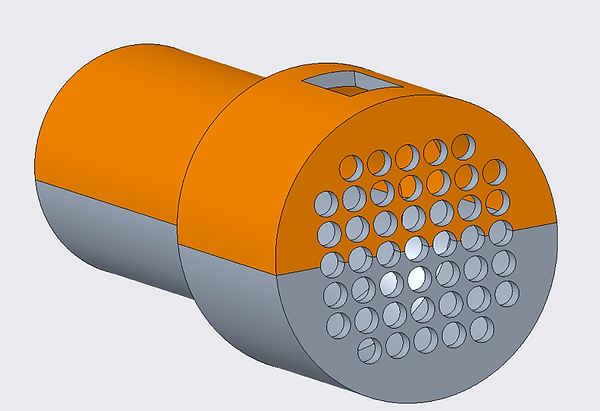

New CAD

Above is the redesign of the hairdryer body. We see this part will be mirrored and fitted together. The final design of the part will include inside features that allow the fan and heater coil to be secured to the inside wall. This part features a 3” diameter shaft that is the perfect size to hold. At the back of the part, the fan blades (which are wider than the ideal hand grip) will be secured inside the larger section of the body. The back features a grill-like pattern that easily allows airflow into the fan compartment without risking user injury (like sticking a finger in the fan blades). The mouth of this hair dryer is left open to be fitted with a number of attachments or diffusers.

Above we see the full assembly. This design would be modified slightly to include screw holes (or hand-operable fasteners as show in redesign idea #3).