New Product DOE

STEP 1

The performance variables for this hair dryer are the speed at which it can dry hair and the amount of energy used in the process of drying the hair. Because this project focused on recyclability, I will focus on the energy efficiency of the hair dryer. Reducing power usage benefits the consumer by costing less energy (although it may take more time to dry the hair) and it benefits the world by requiring less power production (reduces power generation emissions).

The two design variables are fan speed and heating coil power. These two design variables will change the power draw rate and the time it takes to dry the user’s hair.

STEP 2

The target values for response variables are as follows:

Maximum hair drying time--30 minutes

Maximum energy usage--2 MJ

The design variable boundaries are as follows:

Fan setting lowest

Fan setting highest

Heating coil setting highest

Heating coil setting lowest

STEP 3

In this prototype testing, there will be two levels for both design variables. There will be fan setting low (70 watts) and fan setting high (140 watts). Additionally, the other variable will be set as heating coil low (800 watts) and heating coil high (1600 watts). These values are set because if there was too high of an energy consumption, it would heat up the hair dryer and cause discomfort for the user. There are four possible combinations with these design variables. As for the response variables, the hair drying time depends on the length and initial wetness of the user’s hair. Thus, we will conduct all the hair drying test combinations on the same population sample. Ideally, this experiment would run a total of 3 times. 4 combinations 3 times yields a total sample size of 12 tests on the same test users. Because this experiment is sourced from recyclability and design responsibility, it will focus on minimizing energy usage when drying hair.

STEP 4

STEP 5

Predicting Main Equation

Predicting Noise Equation

New Product Cost

The final design of my modified hair dryer is a handle-less dryer with low fan power and high coil heat. Because the fan and motor and heating coil are the same as the original hair dryer, the only parts to perform a piece-part cost analysis on are the two outer shells. The cost of injection molding the two half shells with polypropylene is well under a $1. This is using the estimations and resources used in section 9. The shells are shown below.

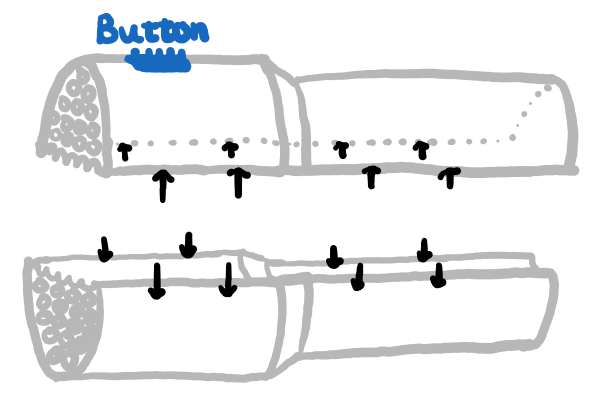

The estimated cost of each shell is around $0.75. There will need to be small holes and tapped threads into both shells for screws to secure This process is sketched below.

The 8 screws will cost close to nothing (around $0.12) and the drilling and tapping process itself will cost an additional estimated $1.00. Thus, a high estimation of the total cost of manufacturing the handle-less shell is in the ballpark of $2.62.

With the same estimated cost of processes for the original and redesign part, the redesigned shell is considerably simpler and cheaper. The redesigned shell has fewer moving parts and a much simpler assembly process. The actual fan/heater system is the same for both parts, but according to the prototype testing values, an optimal fan and heat coil setting was shown to save energy and eliminate variance.